Siemens automation systems provide you with a future-proof answer to increasingly complex plant and machinery requirements. Engineered to meet the needs of all industry sectors in a virtually limitless range of tasks, the superiority of Siemens systems provides peak efficiency, extensive flexibility and high cost effectiveness – in every application.

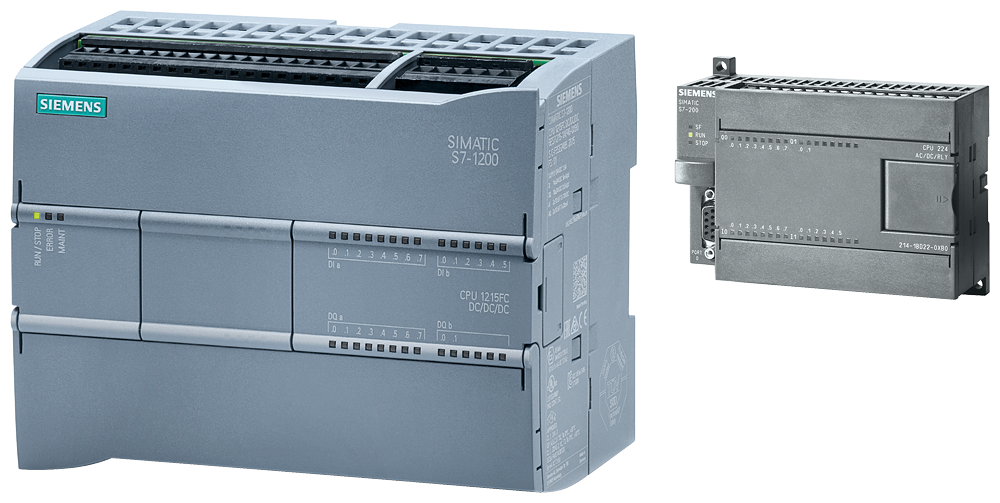

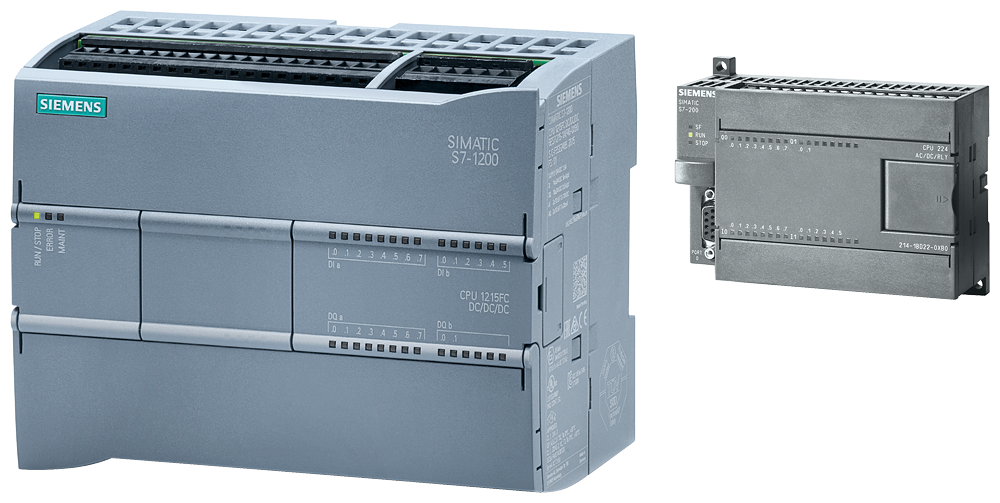

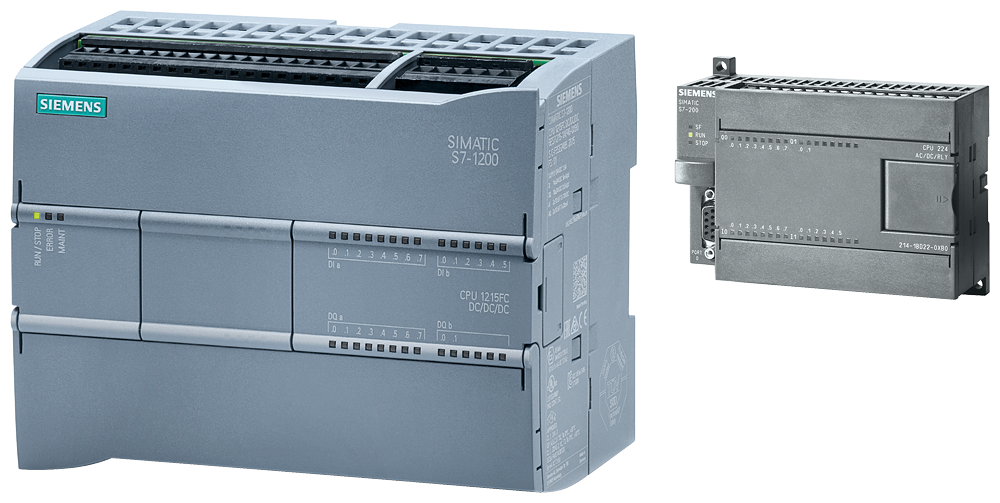

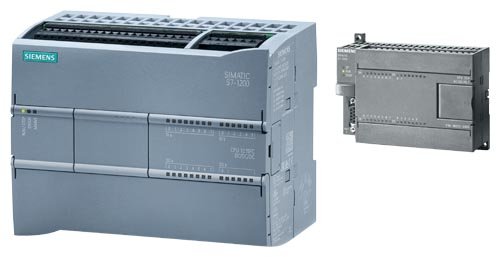

Compact automation solution with requirements for integrated communication and technology functions often combined with cost effectiveness.

Complete production automation and applications for medium-sized and high-end machines with high demands in terms of performance, communication, flexibility and technology functions.

Machines with distributed architecture, series machines, with limited space requirements for the mid-performance range.

Soft Comfort, many solutions for basic machines or plants, in building automation or for a variety of applications all the way into the home can be easily implemented.

The user-friendly and innovative operability of the TIA Portal as well as the integrated system diagnostics contribute to efficient working.

With its many technical inno-vations, the SIMATIC S7-1500 is a milestone in automation and is convincing in terms of system performance and usability.

Small series machines profit from this as well as complex systems with high requirements in terms of performance and functionality for data processing and communication.

With fast signal processing and a variety of built-in communication interfaces, the high-end CPU 1518 provides high productivity and simple integration of office and plant communication.

The S7-1500 is also available in a compact design.

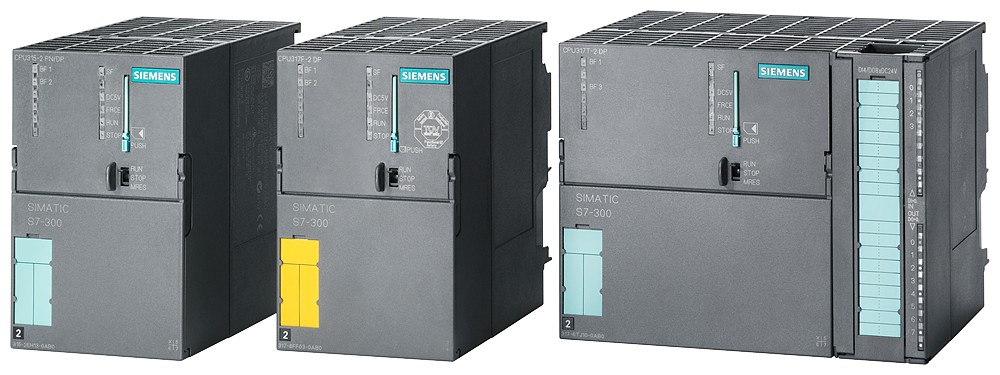

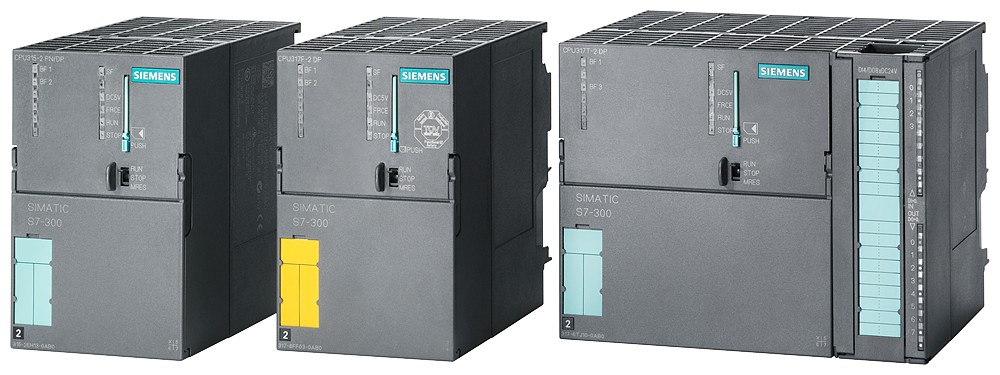

SIMATIC S7-300 is especially designed for system solutions in the manufacturing industry, for example, in the automotive and packaging industries.

The wide range of modules can be used task-specific for central extensions or building decen-tralized structures, and enables cost-effective storage of replacement parts.

Within the SIMATIC Controller range of products, the S7-400 is used both for system solutions in manufacturing and in process automation.

SIMATIC S7-400 is especially suitable for dataintensive tasks, such as those in the process industry.

In the manufacturing industry, for example, it enables high processing speeds and deter-ministic response times for short machine cycle times.

For SIMATIC ET 200SP, inter-face modules with integrated CPU and PROFINET connection are available.

The functionality of the CPUs corresponds to that of the SIMATIC S7-1500.

Using the three integrated Ethernet ports, various connection systems can be realized. Connection to

a superior CPU is realized ana-logous to a standard interface module thanks to the iDevice functionality.

The fail-safe ET 200SP CPUs facilitate the processing of standard and safety program. They are certified for functional safety in accordance with

EN 61508 (2nd edition) and are suitable for safety-related appli-cations up to SIL 3 in accor-dance with IEC 62061 and PL e in accordance with ISO 13849.

SIMATIC S7-300 is especially designed for system solutions in the manufacturing industry, for example, in the automotive and packaging industries.

The wide range of modules can be used task-specific for central extensions or building decen-tralized structures, and enables cost-effective storage of replacement parts.

With its many technical inno-vations, the SIMATIC S7-1500 is a milestone in automation and is convincing in terms of system performance and usability.

Small series machines profit from this as well as complex systems with high requirements in terms of performance and functionality for data processing and communication.

With fast signal processing and a variety of built-in communication interfaces, the high-end CPU 1518 provides high productivity and simple integration of office and plant communication.

The S7-1500 is also available in a compact design.

SIMATIC ET 200 systems are multifunctional, modular and precisely scalable systems for distributed automation. Siemens distributed I/O systems are ideal in control cabinets, at the machine, and in hazardous explosive areas.

All products within the range can be integrated into your existing automation system via PROFIBUS or PROFINET.

SIMATIC ET 200 I/O SYSTEMS FOR USE IN CONTROL CABINETS

With the SIMATIC ET 200, the widest range of I/O systems for solutions in the cabinet is available. The modular design allows the ET 200 system to be scaled up and expanded in easy and small steps: digital and analog inputs/outputs, intelligent modules with CPU functionality, safety technology, motor starters, frequency converters, and diverse technology modules.

I/O Systems of the latest generation

SIMATIC ET 200SP and ET 200MP are part of the new generation of automation devices taking full advantage of the new level of integration offered by the TIA Portal Engineering Framework, the S7-1200 and S7-1500 controllers and Basic and Comfort Panels of the latest generation.

The SIMATIC ET 200SP I/O system is a scalable and highly flexible, distributed I/O system.

The IO system, with its compact design, guarantees the most economical use of the control cabinet.

The ET 200MP I/O system is scalable and is used both as centralized I/O for the Advanced controller S7-1500 and in distributed configurations with ET 200MP Interface Modules.

Tried and tested I/O systems

For existing configurations or special applications in combination with SIMATIC S7-300/400 controllers or for use in hazardous areas the ET 200M and ET 200iSP I/O systems offer a tried and tested automation solution e.g. for the PCS 7 process control system.

SIMATIC ET 200M is the modular I/O station with high density-channel applications especially in connection with SIMATIC S7-300/400 controllers. Applicable Ex analog input or output modules with HART optimize the ET 200M for use in process engineering.

The SIMATIC ET 200iSP is typically used in production facilities of the process industry and offers optimum integration into PCS 7 and other control systems. The intrinsically safe I/O system is suited for direct installation in areas subject to gas or dust explosion hazards.

Tried and tested I/O systems

SIMATIC ET 200 systems for use outside a control cabinet are shock-, dirt- and water-resistant. They are available in a range of models, from the compact block I/O to multifunctional modular systems. You save on supplementary components and space, reduce your cabling requirements, and benefit from extremely short response times.

The rugged I/O with particularly compact design, low space requirements and weight, is specially designed for distributed control electronics in tight spaces and involving motion.

Modular system characterized by a comprehensive range of modules: power modules, CPUs and interface modules, digital and analogue I/O modules, motor starters, frequency converters and an RFID module.

Low-cost, space-saving block I/Os with digital and analog modules and PROFINET connection with 2-port switch in each module

With SIMATIC, users rely on an integrated engineering environment. Efficient software supports users over the entire life cycle of the machine or plant – from the planning and design stages, through configuring and programming, all the way to commissioning, operation and upgrading.

With its integration capability and harmonized interfaces, SIMATIC software permits a high degree of data consistency – throughout the entire engineering process.

STEP 7 (TIA Portal) – Controller software of the new generation

SIMATIC STEP 7 (TIA Portal) continues the success story of SIMATIC STEP 7. With SIMATIC STEP 7 (TIA Portal) users configure, program, test and diagnose the basic, advanced and distributed controllerss of each generation, whether it is PLC- or PC-based, incl. Software controllers.

The price-optimized subset of STEP 7 controller software in the TIA Portal for the Basic Controller SIMATIC S7-1200, including the HMI-Software WinCC Basic

The comprehensive software solution for programming SIMATIC Controllers with a vast number of integrated functions

Functional supplements to the Standard Controller Software, e.g. for failsafe applications or technological tasks

STEP 7 V.5.x – the proven solution with tried and tested functionality

SIMATIC STEP 7 is the world’s best known and most widely used engineering software in industrial automation.

The proven Programming Software for SIMATIC S7-300 / S7-400 and SIMATIC WinAC , and additional editors available as individual components or as a complete package STEP 7 Professional.

In addition to the 5 programming languages of STEP 7 Professional SIMATIC offers further options for programming and design, e.g. for failsafe applications

To keep related costs low, the use of diagnostics tools is recommended. Process diagnostics support maintenance personnel with troubleshooting and fault avoidance.